| March 21, 2022

Odysight.ai®’s patented high-resolution visualization and analysis platform enables early

| March 19, 2022

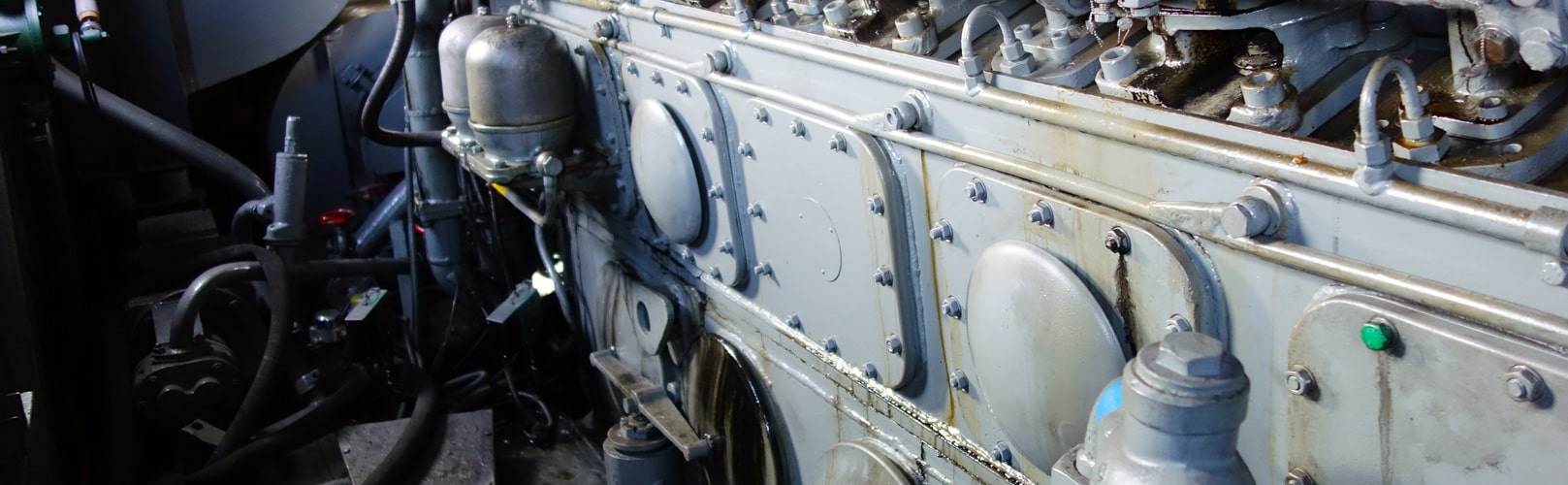

Industry: Mobility (trains) Application: Predictive maintenance for trains .

| March 19, 2022

Industry: Monitoring bearing malfunction and deformation (Aviation, helicopters, civil and

| March 19, 2022

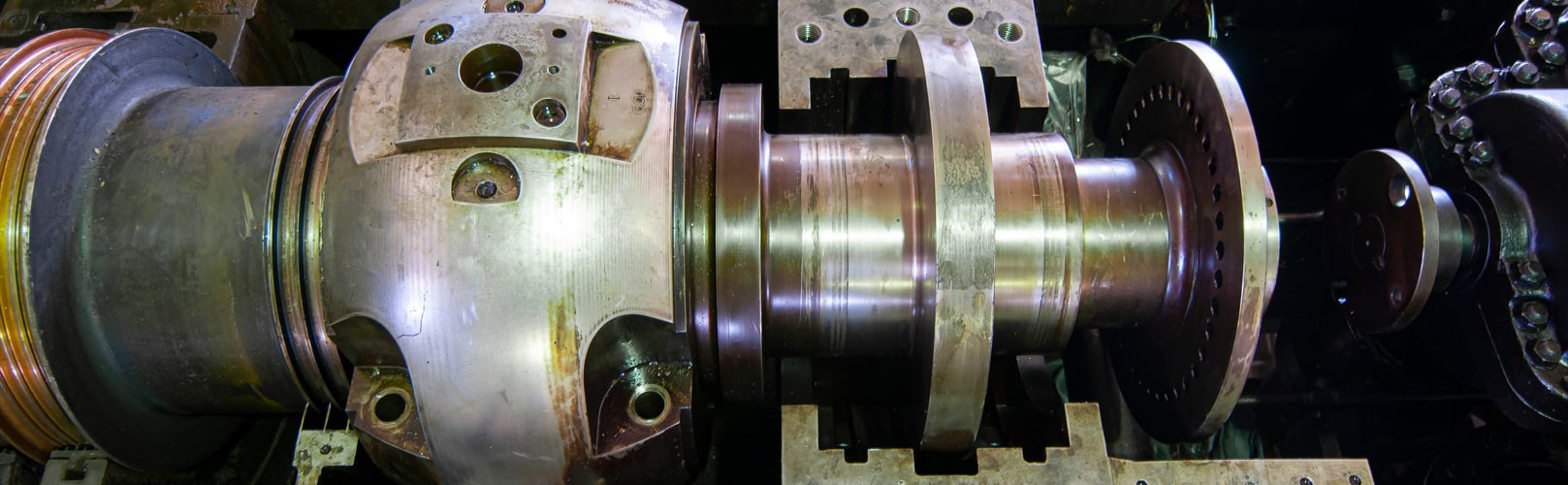

Industry: Aviation Application: Crankshaft inspection for aviation. Odysight.ai®

| March 19, 2022

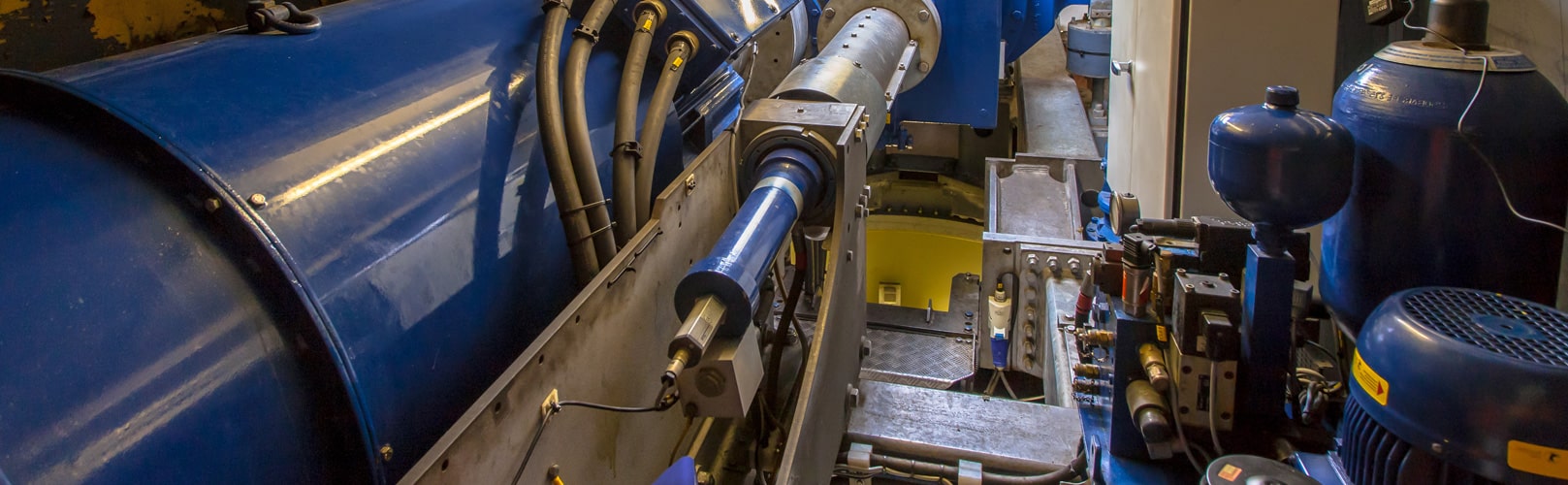

Industry: Mobility, Energy, Aviation and more. Application: Detection of liquid leakage.